SAE 100R7 thermoplastic hydraulic hose is suitable for hydraulic fluids. While it can work at -40 °C-100 °C. 100R7 hose is non-conductive due to its special material. It consists of three parts: tube, reinforce and cover. The tube is made from high quality and oil proof PA. Thus the hose is ideal for petroleum and water based hydraulic fluids. While the reinforce is made from special fiber. Then the cover is made from high quality PU. Thus 100R7 hydrualic hose has good wear resistance. In general, SAE 100 R7 hose has 2 types as follow.

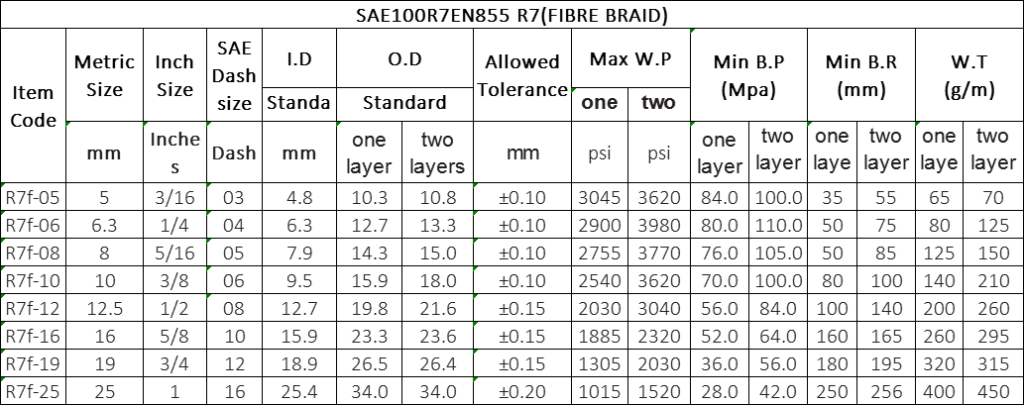

Fiber Braid (Nonmetallic) Resin Hose SAE 100R7

INNER TUBE: Oil proof Polyamide (PA)

REINFORCE: one or two layers of high tensile synthetic fibre braid.

COVER: Black and high wear resistant PU

APPLICATION: Medium pressure hydraulic and pneumatic systems. Exceeds SAE 100R7 standard. It’s also ideal for pneumatic and gaseous systems, use perforated (pin-pricked) hose.

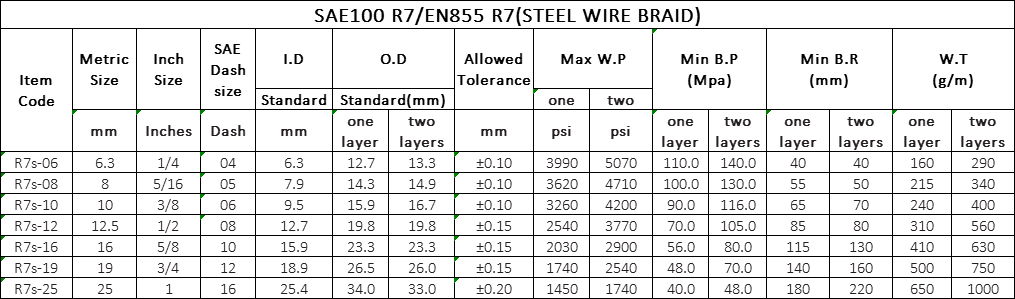

Steel Wire Braid Resin Hose

INNER TUBE: Oil proofPolyamide (PA)

REINFORCE: one or two layers of high tensile steel wire braid

COVER: Black and high abrasion resistant PU

APPLICATION: Medium pressure hydraulic and pneumatic systems. Exceeds SAE 100R7. It’s also ideal for pneumatic or gaseous systems, use perforated (pin-pricked) hose.

TEMPERATURE RANGE: -40℃ (-104 ℉ ) to 100℃ (+212 ℉)

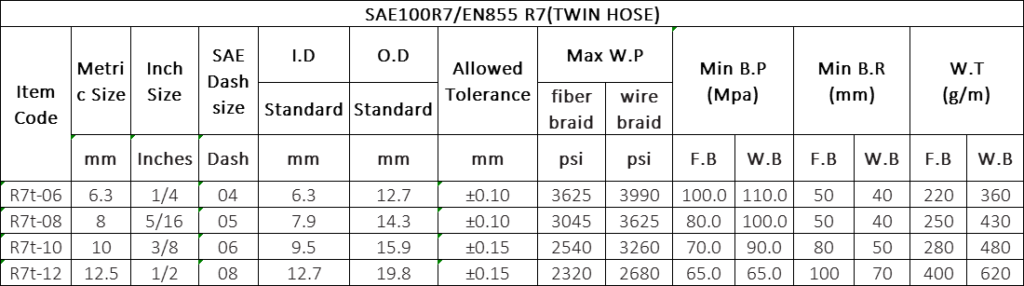

Fibre Or Wire Braid Resin Twin Hoe

INNER TUBE: Oil proof Polyamide (PA)

REINFORCE: one or two layers of high tensile synthetic fibre braid

COVER: Black and high abrasion resistant PU

TEMPERATURE RANGE: -40℃ (-104 ℉ ) to +100℃(+212 ℉)

TEMPERATURE RANGE: -40℃ (-104 ℉ ) to +100℃(+212 ℉)

Raw Material:

Our hydraulic hose SAE 100 R7 is made from Nylon that imported from Japan.

With the imported materials, our hose get more stronger heat & temperature resistance and high tensile strength

The temperature range is from -40℃ to 120℃ .

Factory Workshop:

Our factory introduce advanced technology and equipment to make the best quality hydraulic hose.

High speed braiding machine makes the reinforcement layer more steady.

Laboratory:

Laboratory:

Our factory has strong quality control team and we set up advanced laboratory.

Before the production, we test each batch of raw material.

After the production, we test each hose to guarantee a 100% qualification.

Each hose is tested 2 times on working pressure.

We do everything that possible to supply good quality goods for our customer.

After finishing the Hydraulic Hose production, we will pack the hose. In general, the packing will

use woven bag and plastic film. Special packing is available according to customers’ requirements.